In conclusion, our Electric Pipe and Tube Bending Machines stand as the epitome of excellence for businesses seeking to elevate their metalworking capabilities. Specializing in high-quality Electric Pipe and Tube Bending Machines our products at Gulf States Saw & Machine Co. are designed for precision and reliability in industrial settings. With advanced technology and sturdy construction, our machines offer efficient bending capabilities for various metal pipes and tubes. We prioritize customer satisfaction by providing tailored solutions to meet specific bending needs and requirements. Trust us to deliver top-notch equipment that enhances productivity and streamlines manufacturing processes in diverse industries.. With our unwavering commitment to quality, innovation, and customer satisfaction, we aspire to be your trusted partner in the industry.

Experience the epitome of innovation and precision in metalworking with our premier selection of Electric Pipe and Tube Bending Machines. Tooling Crafted with cutting-edge technology and meticulous attention to detail, each machine in our lineup promises unparalleled performance and reliability.

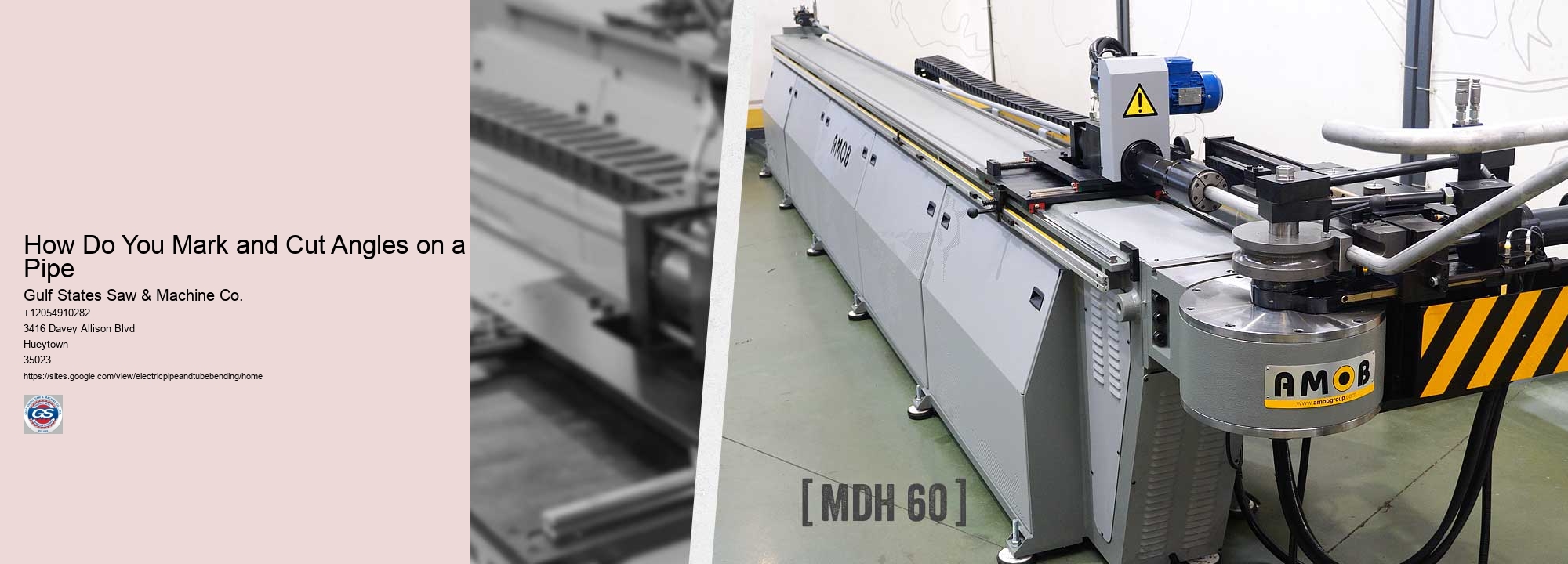

Explore our diverse range of Electric Pipe Bender Machines and Tube Benders to find the perfect solution for your bending needs. Whether you're tackling intricate projects or heavy-duty industrial tasks, our machines are engineered to meet the demands of any application.

Unlock seamless operation and maximum productivity with our Electric Pipe and Tube Bending Machines, equipped with advanced automation features. Whether you're fabricating handrails, constructing architectural structures, or manufacturing intricate components, our machines deliver consistent, precise results with minimal effort.

At our facility, we uphold the highest standards of quality to ensure that each Electric Pipe and Tube Bending Machine surpasses expectations in terms of durability and efficiency. Our team of skilled engineers and technicians is dedicated to continuous innovation, ensuring that our products remain at the forefront of technological advancements in the industry.

In addition to our standard offerings, we provide customization options to accommodate specific customer requirements. Whether you need specialized bends or unique configurations, our team can tailor our machines to suit your precise needs.

Our company stands out as a beacon of excellence in providing a top-tier selection of Electric Pipe and Tube Bending Machines, meticulously engineered to cater to the diverse requirements of industrial metalworking operations. With a fusion of state-of-the-art technology and precision craftsmanship, we proudly offer an extensive array of Electric Pipe Bender Machines and Tube Benders, ensuring seamless and accurate bending processes.

Embedded with advanced automation features, our Electric Pipe and Tube Bending Machines offer a seamless operation experience, thereby maximizing productivity in manufacturing and fabrication settings. Whether you're in need of a compact Electric Pipe Bender or a heavy-duty Hydraulic Tube and Pipe Bender, rest assured, we have the ideal solution perfectly aligned with your unique specifications.

Among our flagship offerings lies the Electric Pipe Bender, revered for its unmatched performance and unwavering reliability. Capable of handling a diverse range of pipe diameters and materials, our Electric Hydraulic Pipe Bender offers unparalleled versatility and adaptability in bending applications. Supplier Furthermore, our Electric Tube Bender Machines are meticulously engineered to deliver precise bends with minimal effort, making them indispensable for even the most demanding metalworking tasks.

At our state-of-the-art facility, we uphold stringent quality standards to ensure that each Electric Pipe and Tube Bending Machine meets the highest levels of durability and efficiency. Our team of seasoned engineers and technicians works tirelessly to innovate and refine our product lineup, ensuring we remain at the vanguard of the industry's technological advancements.

In addition to our standard Electric Pipe and Tube Bending Machines, we offer bespoke customization options to cater to specific customer requirements. Whether you require a specialized J-bend Pipe or a custom U-bend Pipe, our adept team can tailor our machines to perfectly suit your unique needs and preferences.

We understand the paramount importance of precision and accuracy in Electric Pipe and Tube Bending Machines. Industrial That's why our machines are equipped with cutting-edge CNC technology and precision machining capabilities, guaranteeing consistent and reproducible results with every bend.

For customers seeking cost-effective solutions without compromising on quality, we present a diverse range of meticulously refurbished Electric Pipe and Tube Bending Machines that deliver exceptional performance at a fraction of the cost.

In essence, our Electric Pipe and Tube Bending Machines epitomize excellence for businesses seeking to elevate their metalworking capabilities.

Certainly!

Welcome to our realm of precision engineering and innovation, where Electric Pipe and Tube Bending Machines reign supreme. Within our domain, excellence is not just a standard; it's the cornerstone of everything we do.

Prepare to embark on a journey of unparalleled efficiency and accuracy with our Electric Pipe and Tube Bending Machines, meticulously crafted to meet the exacting demands of industrial metalworking operations. Whether you're navigating the intricate intricacies of fabrication or shaping the future of manufacturing, our machines stand ready to meet your every need with precision and grace.

Immerse yourself in the seamless operation of our Electric Pipe and Tube Bending Machines, where advanced automation features seamlessly integrate with your workflow to maximize productivity and efficiency. From intricate bends to complex curves, our machines deliver flawless results with every operation, ensuring that your projects exceed expectations time and time again.

Experience the epitome of reliability and performance with our flagship Electric Pipe Bender, renowned for its exceptional capabilities and unwavering durability. Engineered to handle a diverse range of pipe diameters and materials, our Electric Hydraulic Pipe Bender empowers you to tackle even the most challenging bending tasks with ease and confidence.

At the heart of our operation lies a commitment to excellence, reflected in every aspect of our Electric Pipe and Tube Bending Machines.

In addition to our standard offerings, we offer bespoke customization options tailored to your specific requirements.

Factors to consider when selecting an electric bending machine include bending capacity, material compatibility, and cost.

While electric bending machines offer high precision and efficiency, they may have limitations on the maximum bending radius or material thickness.

Yes, electric bending machines can bend pipes and tubes made of various materials, including steel, stainless steel, copper, and aluminum.

Electric pipe and tube bending machines are industrial equipment used to bend metal pipes and tubes using electric power.

The advantages of electric bending machines include precision, efficiency, and the ability to produce consistent bends.